PRODUCTION PLANTS

What are the features that make the production of an adhesive tape unique and inimitable?

Quality of raw materials

Experience

Attention to detail

Flexibility

And advanced technology plants designed for maximum production efficiency and reduced environmental impact.

Quality of raw materials

Experience

Attention to detail

Flexibility

And advanced technology plants designed for maximum production efficiency and reduced environmental impact.

ADHESIVE PREPARATION

Autoadesivi Magri has a department totally dedicated to adhesive preparation.

This complex industrial process requires a special equipment, such as natural rubber grinding systems, resins and dissolvers handling pneumatic conveyors which treat the various ingredients to make the adhesive.

To ensure long-term tapes adhesion and adhesive properties maintainance, Autoadesivi Magri constantly checks the entire adhesive production process from the raw materials to the accessory mixtures.

This complex industrial process requires a special equipment, such as natural rubber grinding systems, resins and dissolvers handling pneumatic conveyors which treat the various ingredients to make the adhesive.

To ensure long-term tapes adhesion and adhesive properties maintainance, Autoadesivi Magri constantly checks the entire adhesive production process from the raw materials to the accessory mixtures.

ADHESIVE COATING PLANTS

Two complete coating lines:

Natural rubber adhesive line

Hot Melt adhesive line

They allow the production of PET, BOPP, PVC and PAPER tapes.

These plants can guarantee high quality production and efficient control of the adhesive quantity applied.

https://www.youtube.com/watch?v=GqMcb2btq0si

Natural rubber adhesive line

Hot Melt adhesive line

They allow the production of PET, BOPP, PVC and PAPER tapes.

These plants can guarantee high quality production and efficient control of the adhesive quantity applied.

https://www.youtube.com/watch?v=GqMcb2btq0si

Previous slide

Next slide

Previous slide

Next slide

CUTTING AND PACKAGING LINES

With 10 complete cutting lines and a production capacity of over 500,000 square metres of adhesive tape per work shift(*), our department is a model of efficiency and extraordinary production capacity.

This not only allows us to meet current demand, but also makes us able to manage peak demand or seize new market opportunities.

We can count on our flexibility and ability to adapt to evolving customer needs.

(*) Average value, 2022.

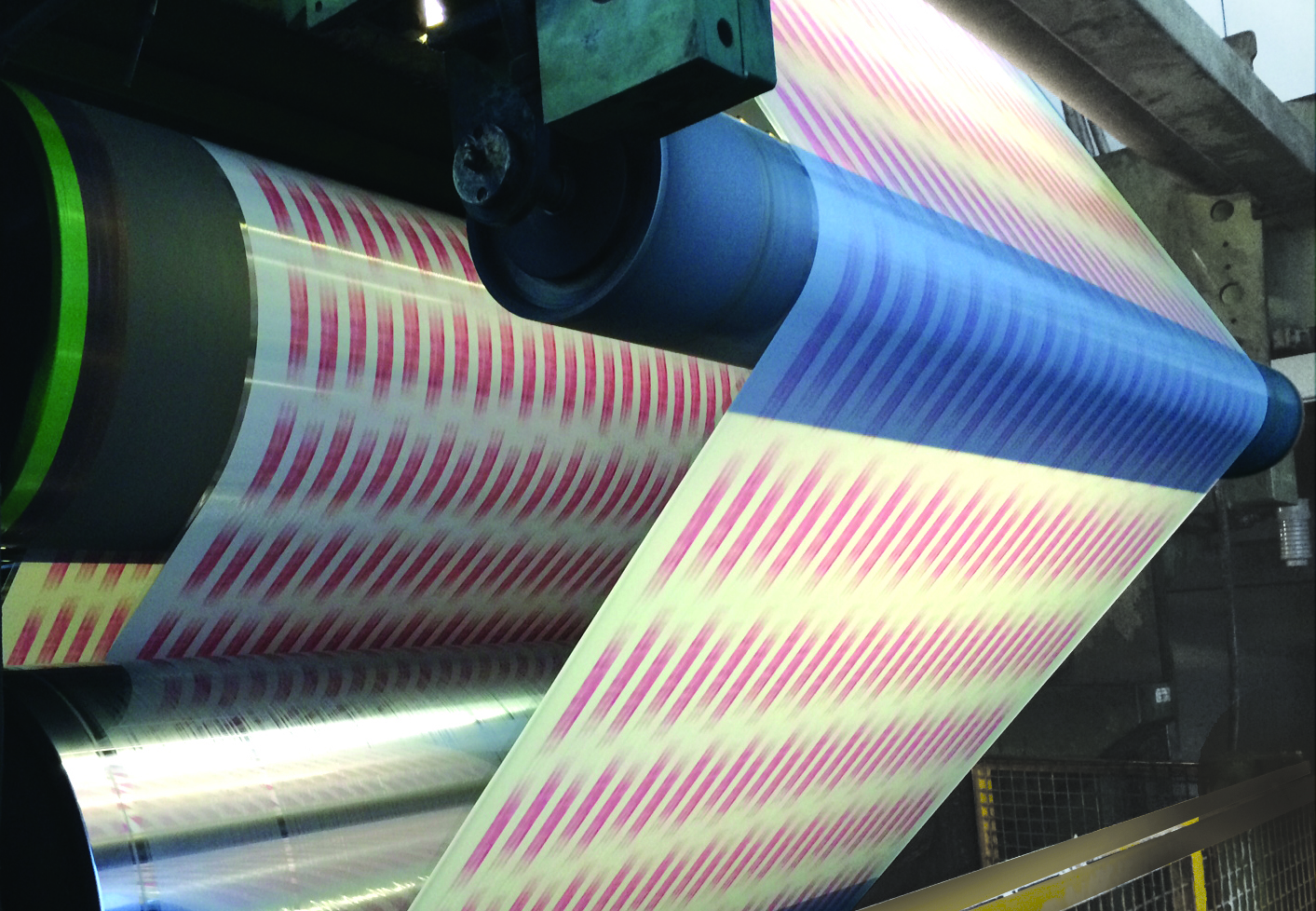

PRINTING DEPT. FOR ADHESIVE TAPE CUSTOMISATION

The 8 production stations printing department allows to print on all types of support, both ‘ON THE TOP’ and ‘PREPRINTED’, offering our customers the possibility to customize their own adhesive tape.

We internally draw the artworks with the personalized logo required from the customer.

From the graphics department, which prepares the artwork and submits them to the customer for approval, to the production of cliché via CTP, to the printing of the tape.

In this way we meet all customers requirements and to speed up

delivery times.